LEARN MORE ABOUT ANDRONACO INDUSTRIES

PIPING PRODUCTS

EXPANSION JOINTS

STRAINERS

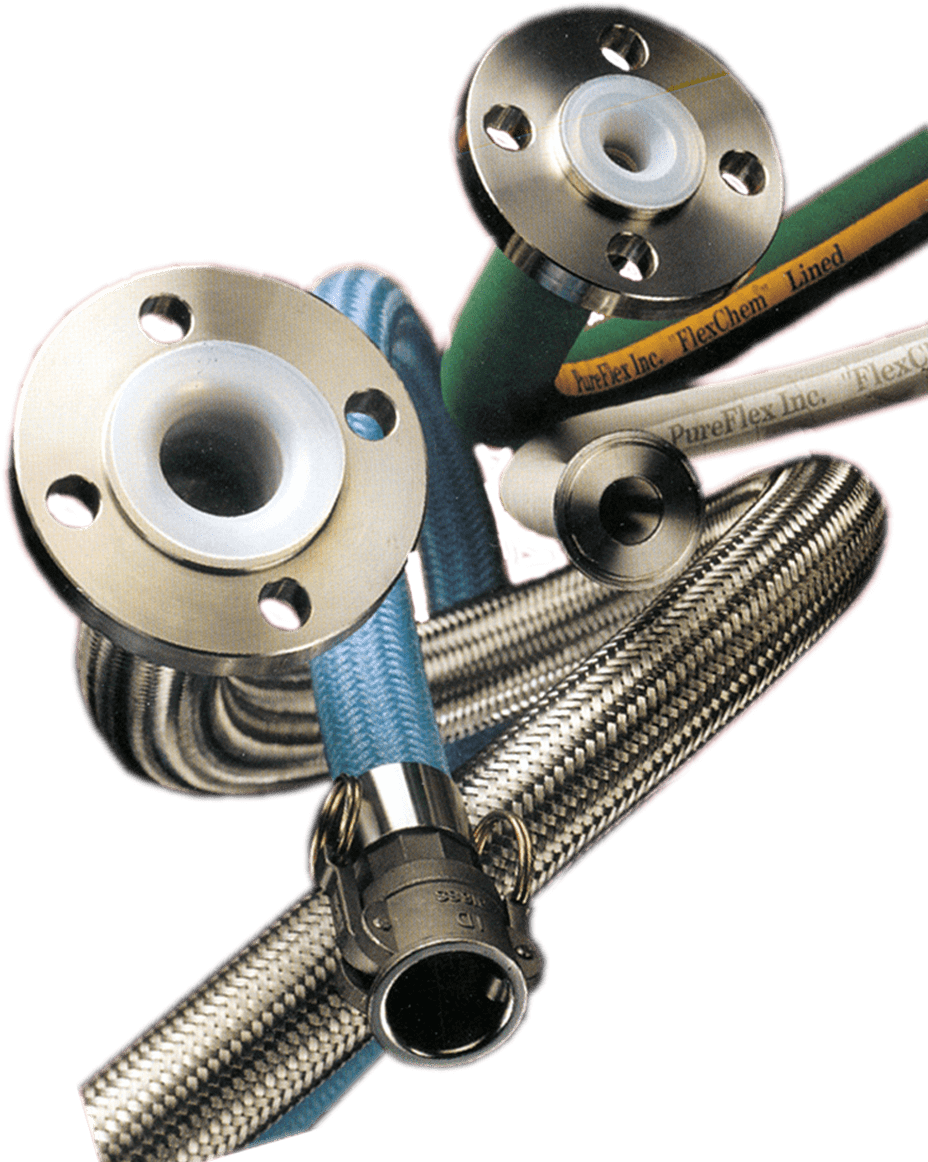

HOSES

SIGHT FLOW INDICATORS

SAMPLING SYSTEMS

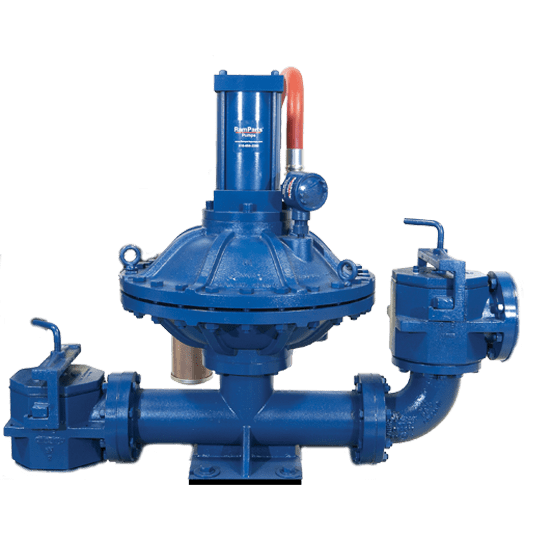

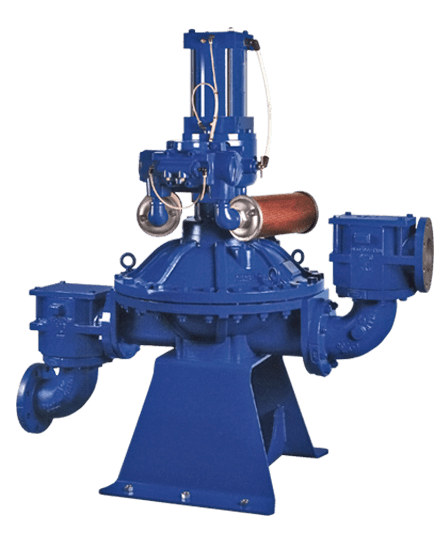

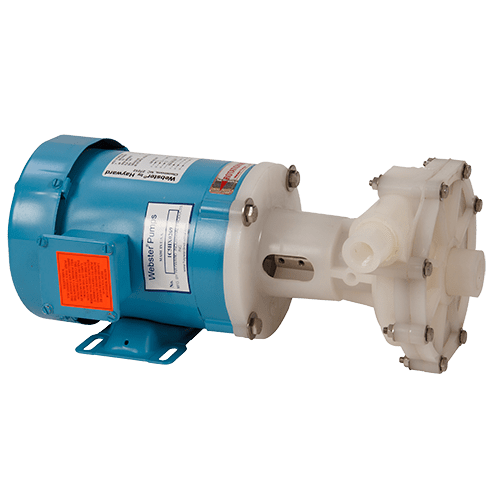

DIAPHRAGM PUMPS